Lens Type Expansion Joint – Complete Technical Guide, Design Principles, Applications & Manufacturing Standards

Lens type expansion joints are engineered mechanical components designed to absorb thermal expansion, axial movement, vibration, and pressure fluctuations in industrial piping systems. Known for their durability, high-pressure resistance, and leak-proof performance, lens type expansion joints (also referred to as lens type compensators or thick wall expansion joints (lens)) are widely used in power plants, refineries, petrochemical facilities, district heating networks, and chemical processing lines.

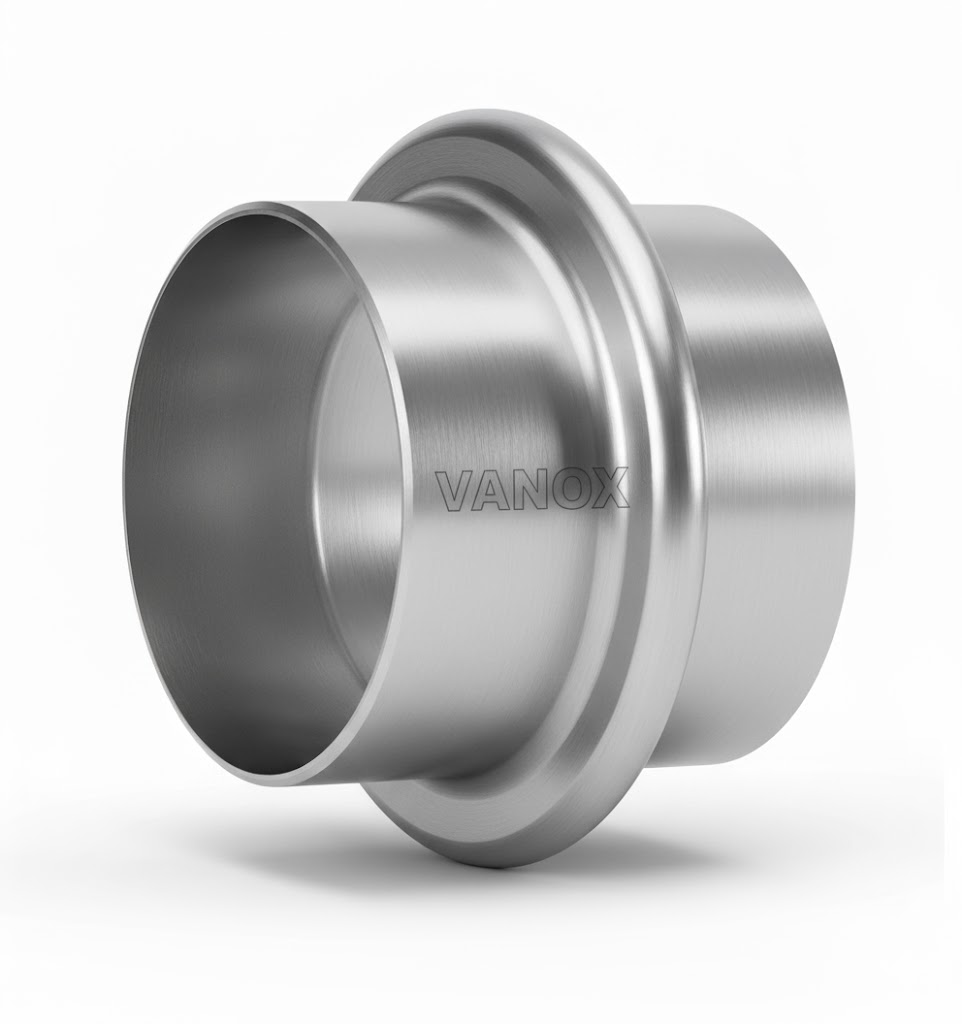

Manufactured in Turkey by Vanox with advanced forming, welding, and testing technologies, these expansion joints provide long-term reliability even under extreme temperatures and demanding operational conditions. This comprehensive guide explores their engineering, design, advantages, applications, materials, manufacturing processes, installation guidelines, and quality assurance procedures in detail.

1. What Is a Lens Type Expansion Joint?

A lens type expansion joint is a pressure-containing expansion device created by welding two formed steel plates to build a lens-shaped profile. Unlike thin-wall bellows expansion joints, lens type compensators are constructed from thick metal sections, making them suitable for:

- High-pressure pipelines

- High-temperature steam and thermal oil lines

- District heating and long-distance transport networks

- Harsh industrial environments with large temperature gradients

The architecture of the lens-type design distributes stress evenly across the geometry, significantly reducing fatigue failures and ensuring stable mechanical performance throughout the pipeline’s lifecycle.

Main Functions of Lens Type Expansion Joints

- Absorbing axial movements caused by thermal expansion

- Compensating for vibrations and pressure pulsations

- Reducing mechanical loads on pumps, boilers, and equipment

- Maintaining leak-free operation in high-pressure systems

- Protecting piping networks from stress concentration

2. Construction and Design Characteristics

At the core of the lens type expansion joint is the welded lens element. Two dished metal plates are shaped using hydraulic presses or spinning machines, then welded at the edges to form a robust, single-lens module. Depending on the project requirements, a single-lens, multi-lens, or custom engineered configuration may be used.

2.1 Lens Geometry

The unique geometry of the lens section allows the joint to flex slightly under pressure, distributing forces across a larger surface area than conventional corrugated expansion joints. This results in:

- Lower bending stress

- Greater resistance to cyclic fatigue

- Improved sealing at high operational pressures

- Higher reliability in extreme thermal cycles

2.2 Wall Thickness and Material Selection

Lens type compensators are generally considered thick wall expansion joints (lens) due to their solid and heavy-duty construction. The wall thickness typically ranges from 4 mm to 20+ mm depending on:

- Operating pressure

- Temperature

- Movement absorption capacity

- Corrosive properties of the transported medium

Common materials used by Vanox include:

- Carbon Steel (A516 Gr. 60/70, St37, St44, St52)

- Stainless Steel (304, 316, 321, 316Ti)

- Duplex & Super Duplex Steel

- Alloy Steels (P11, P22, P91)

The correct material selection ensures corrosion resistance, structural stability, and extended operational life.

2.3 Welded Construction

Welding quality is critical because the lens plates form a pressure vessel. Vanox applies:

- Semi-automatic and fully automatic MIG & TIG welding

- Weld penetration control by ultrasonic testing

- Radiographic examination for full quality validation

3. Applications of Lens Type Expansion Joints

Lens type expansion joints are favored in industries where reliability and pressure resistance are essential. Their strong construction makes them ideal for both standard and extreme pipelines.

3.1 Power Plants

In thermal power plants, high-temperature steam expands significantly, producing axial movement within the pipes. Lens type expansion joints compensate these movements while ensuring leak-free operation.

3.2 Petrochemical and Refining Industry

Because of their ability to withstand corrosive chemicals and continuous temperature fluctuations, lens type compensators are a standard component in refineries and chemical processing plants.

3.3 District Heating and Cooling Systems

These networks require long-term flexibility and durability. Thick wall lens expansion joints prevent stress accumulation throughout the pipeline and reduce the need for frequent maintenance.

3.4 High-Pressure Steam and Gas Lines

Systems operating above 40 bar often prefer lens type expansion joint designs due to their pressure-bearing capacity and double-welded sealing zones.

4. Advantages of Lens Type Expansion Joints

Lens type compensators offer several specific advantages over traditional corrugated bellows expansion joints:

- Superior pressure resistance thanks to thick wall construction

- Longer service life in high-cycle systems

- Exceptional fatigue resistance due to optimized geometry

- Leak-free operation under dynamic loads

- High structural stability in large diameter pipelines

- Low maintenance requirements with welded design

These benefits make lens-type joints a preferred choice in mission-critical infrastructure where downtime is unacceptable.

5. Manufacturing Process at Vanox

Vanox in Turkey manufactures lens type expansion joints according to international standards such as EN, ASME, EJMA, and PED. The production process includes:

5.1 Metal Forming

- Dished plates produced using hydraulic pressing

- Edge forming and precision shaping

- Dimensional control for perfect symmetry

5.2 Welding & Assembly

- Circumferential welding with controlled heat distribution

- NDT-controlled joint integration

- Multi-lens modules assembled for higher movement absorption

5.3 Coating and Surface Protection

- Anti-corrosion paint systems

- Internal coatings for chemical media

- Shot blasting and protective finishing

6. Testing and Quality Assurance

Each lens type expansion joint manufactured by Vanox undergoes stringent testing procedures:

- Hydrostatic Pressure Test – Ensures strength and leak tightness

- UT (Ultrasonic Testing) – Validates weld penetration

- RT (Radiographic Testing) – Detects internal flaws

- Dimensional Inspection – Ensures compliance with design tolerances

- Material Certification – Confirms correct alloy selection

All tests are performed according to international quality standards such as ISO 9001 and EN 10204 3.1 certification requirements.

7. Installation Guidelines

Proper installation is essential for the reliable performance of lens type expansion joints. Key recommendations include:

- Install in straight pipe sections to maximize movement absorption

- Ensure pipeline alignment to avoid lateral loads

- Support the piping system to prevent unnecessary forces

- Follow bolt tightening sequences for flange-type connections

- Check for correct axial installation length

8. Maintenance & Service Life

While lens type compensators are considered “low-maintenance” components, periodic inspections enhance service life:

- Check weld areas for external corrosion

- Verify movement capability during thermal cycles

- Inspect mounting bolts on flanged models

- Review surface coating condition

With proper installation and operating conditions, a lens type expansion joint can exceed 20+ years of operational life.

Conclusion

Lens type expansion joints are among the most durable and technically reliable expansion solutions for high-pressure and high-temperature industrial pipelines. Their thick wall construction, welded lens geometry, and excellent fatigue resistance make them suitable for mission-critical applications across multiple industries. Manufactured by Vanox with advanced engineering and international quality standards, these joints ensure long-term safety, precision, and performance in even the most demanding environments.

Keywords: lens type expansion joints, lens type expansion joint, lens type compensator, Thick Wall Expansion Joints (Lens)

Frequently Asked Questions

Below are examples of fabric expansion joints manufactured by Vanox for high-temperature duct systems.