Rectangular expansion joints are critical components used to absorb thermal expansion, vibration, and mechanical movement in ducting systems. Vanox manufactures high-quality rectangular expansion joints designed for durability, flexibility, and long-term performance across a wide range of industrial applications. Engineered with precision and built using premium materials, Vanox rectangular expansion joints are essential for maintaining the reliability and safety of ventilation, exhaust, and process duct systems.

What Are Rectangular Expansion Joints?

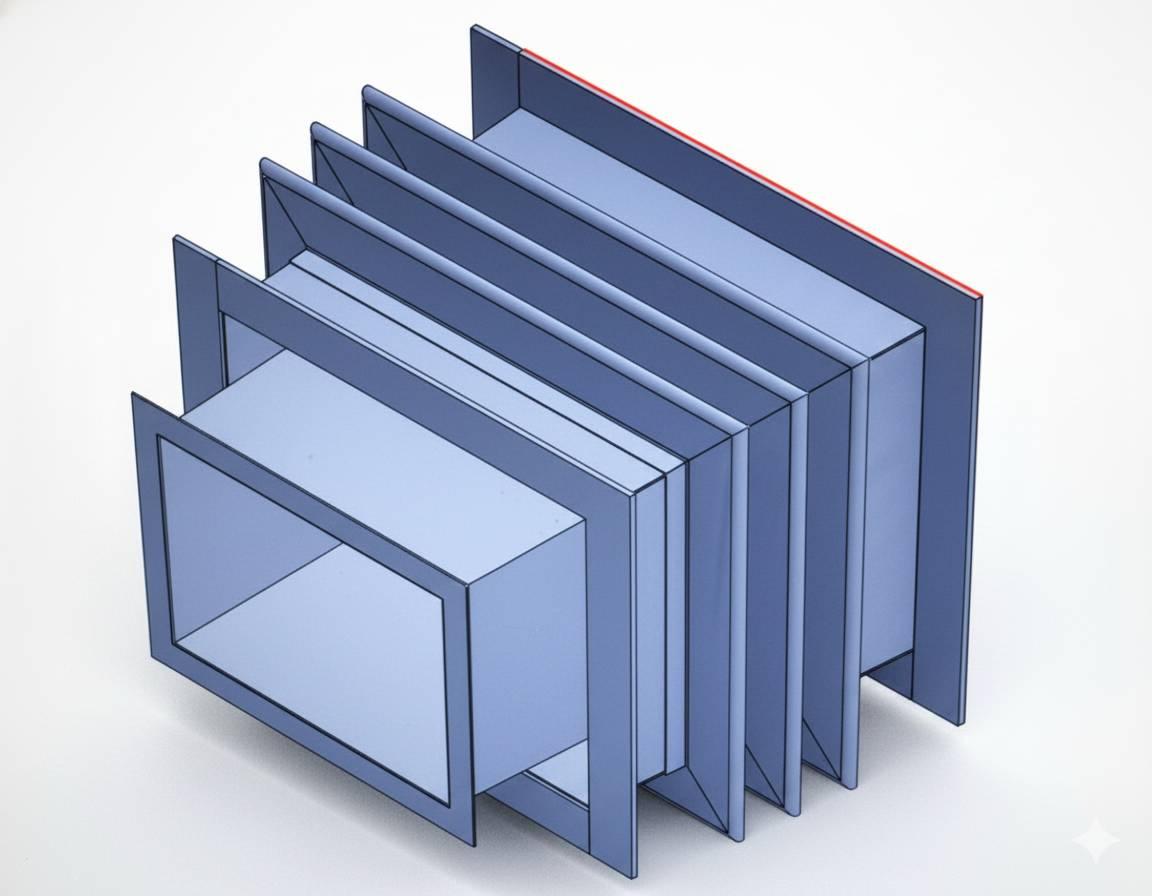

Rectangular expansion joints are flexible metal devices designed to compensate for thermal growth and movement in rectangular ducting systems. When ducts are exposed to temperature fluctuations, they expand and contract. Without expansion joints, this movement can cause stress, deformation, or even catastrophic failure of the ducting system. Vanox rectangular expansion joints prevent these issues by effectively absorbing axial, lateral, and angular movements. The bellows of these joints are typically made from austenitic stainless steel or carbon steel, carefully selected based on service conditions. Vanox offers a wide range of material choices, including stainless steel grades SS304, SS321, and SS316. These materials ensure excellent resistance to corrosion, high temperatures, and demanding operating environments.

Design Features of Vanox Rectangular Expansion Joints

Vanox manufactures rectangular expansion joints using advanced fabrication techniques and strict quality standards. These joints can be produced with:

- Straight corners

- U-shaped convolution corners

- Rounded corners

- Double mitre corners

- Square corner configurations

The rectangular design allows these joints to absorb movement in two perpendicular directions, making them ideal for installations with limited space or unique structural constraints. Vanox specializes in straight-corner and U-shaped convolution designs, offering exceptional performance for both low- and moderate-pressure applications.

How Rectangular Expansion Joints Work

The bellows consist of multiple corrugations that provide flexibility. When ductwork expands or contracts due to temperature changes, the corrugations compress or extend accordingly, thereby absorbing the movement without transferring stress to adjacent equipment. This prevents fatigue damage, misalignment, and structural issues, ensuring long-term system integrity. Additionally, Vanox offers optional accessories such as:

- Internal sleeves – to protect bellows against abrasion and smooth airflow.

- Limit rods – to control excessive movements.

- Control rods – to restrict lateral loads.

- Hinges – to manage angular movement.

These accessories enhance system protection and ensure reliable operation even under demanding conditions.

Applications of Vanox Rectangular Expansion Joints

Rectangular expansion joints are widely used in various industries where ducting systems experience significant thermal movement or vibration. Typical applications include:

- Ventilation systems

- Air ducts and HVAC systems

- Exhaust and fan systems

- Gas turbine ducts

- Chemical processing systems

- Steel and iron plants

- Cement plants

- Power generation facilities

In power plants, Vanox rectangular expansion joints are used near steam and gas turbine systems, especially where vacuum conditions or rapid temperature changes occur. In petrochemical facilities, these joints withstand corrosive gases and high-temperature environments, ensuring safe and reliable operation. In the cement and steel industries, Vanox expansion joints handle heavy-duty thermal loads in dust-laden or high-temperature ducting systems.

Benefits of Vanox Rectangular Expansion Joints

Vanox rectangular expansion joints offer numerous advantages, making them a superior choice in demanding industrial environments. Key benefits include:

- Thermal Movement Absorption: Effectively compensates for duct expansion and contraction, preventing structural stress.

- Vibration Isolation: Dampens equipment and flow-induced vibrations, improving system reliability.

- Misalignment Compensation: Helps correct minor installation or alignment deviations.

- High Durability: Premium materials ensure long service life even under extreme conditions.

- Custom Manufacturing: Vanox designs each rectangular expansion joint to meet specific size, pressure, and movement requirements.

- Compliance with Industry Standards: Manufactured following EJMA (Expansion Joint Manufacturers Association) guidelines.

These features make Vanox a trusted partner for engineers, contractors, and industrial operators seeking reliable duct expansion solutions.

Vanox Manufacturing Capabilities

Vanox offers fully customizable rectangular expansion joints. Units can be supplied as:

- Single rectangular expansion joints

- Universal rectangular expansion joints

Manufacturing options include:

- Weldable pipe ends for welded installation

- Flange ends with customizable drilling patterns

- Double bellows configurations

- Round or bevel corners depending on system requirements

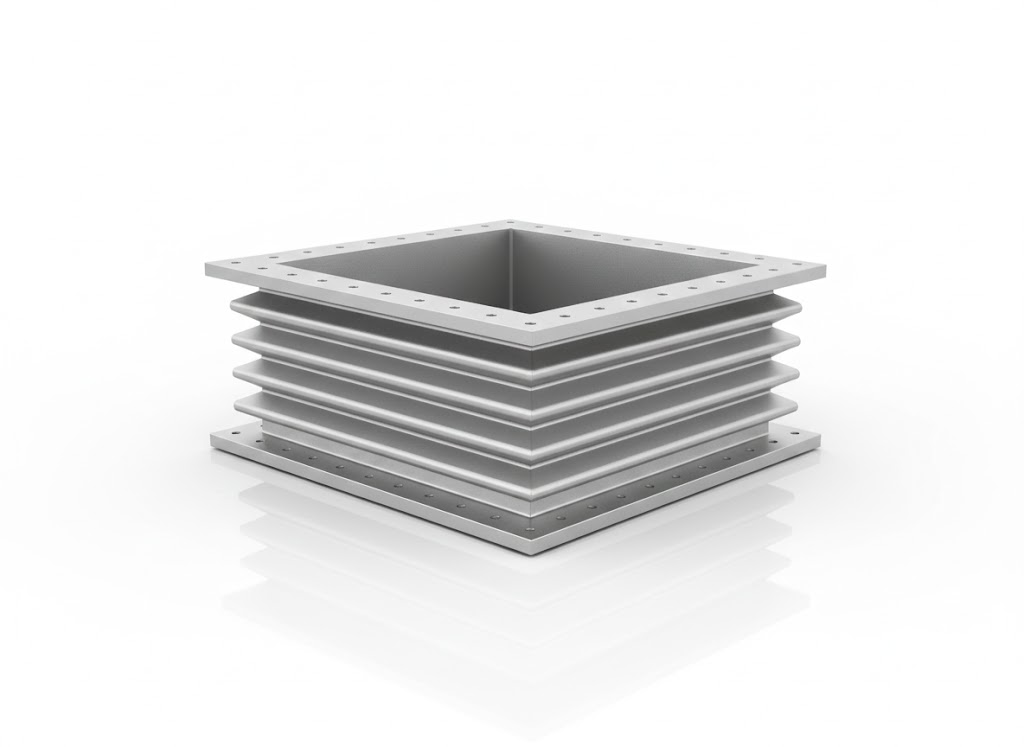

Square expansion joints

Square expansion joints are specially designed flexible elements used in ducting and piping systems to absorb thermal movement, vibration, and mechanical stress in installations with square or box-shaped geometries. They function similarly to rectangular metal expansion joints but feature equal-length sides, making them ideal for systems where uniform load distribution and symmetrical movement are required. Square expansion joints are typically manufactured using stainless steel or carbon steel bellows, engineered to handle axial, lateral, and angular movements while maintaining structural integrity. Their rigid yet flexible design ensures reliable performance in ventilation ducts, exhaust systems, industrial furnaces, and high-temperature flue gas lines. Square expansion joints also help prevent misalignment issues, reduce stress on connected equipment, and extend the operational lifespan of ducting systems.

Industry Examples and Use Cases

- Nuclear power plants: Used in high-reliability duct applications.

- Petrochemical plants: Handles corrosive gases and thermal variations.

- Steel and iron plants: Supports high temperature and vibration conditions.

- Cement industries: Installed in scrubbers, ID/FD fans, and gas pre-heaters.

These examples demonstrate the versatility and reliability of Vanox rectangular expansion joints across diverse industrial sectors. Vanox rectangular expansion joints provide high-performance, durable, and flexible solutions for managing thermal movement and vibration in ducting systems. With advanced manufacturing capabilities, customizable designs, and adherence to international standards, Vanox ensures long-lasting and efficient operation across HVAC, industrial, and heavy-duty applications. Whether used in power plants, petrochemical facilities, steel mills, or ventilation systems, Vanox rectangular expansion joints deliver superior performance and unmatched reliability. Their ability to absorb axial, lateral, and angular movement makes them indispensable for maintaining system integrity and reducing maintenance costs. For engineers and industry professionals seeking robust expansion solutions, Vanox offers cutting-edge technology, precision engineering, and industry-leading expertise in rectangular expansion joint manufacturing.

Below are examples of Vanox fabric expansion joints engineered for thermal expansion and vibration control in ducting systems.

|  |