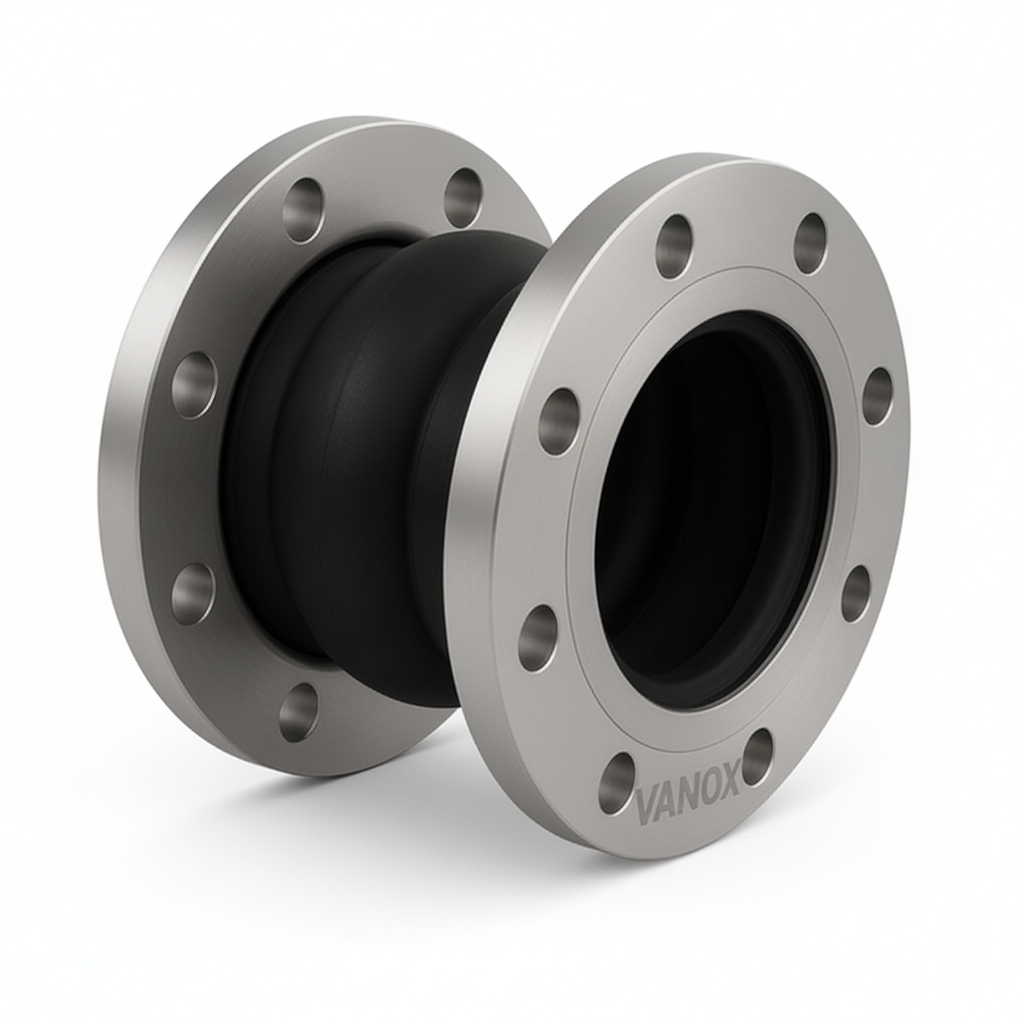

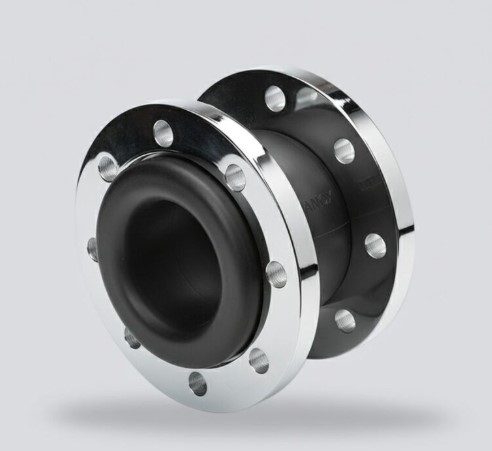

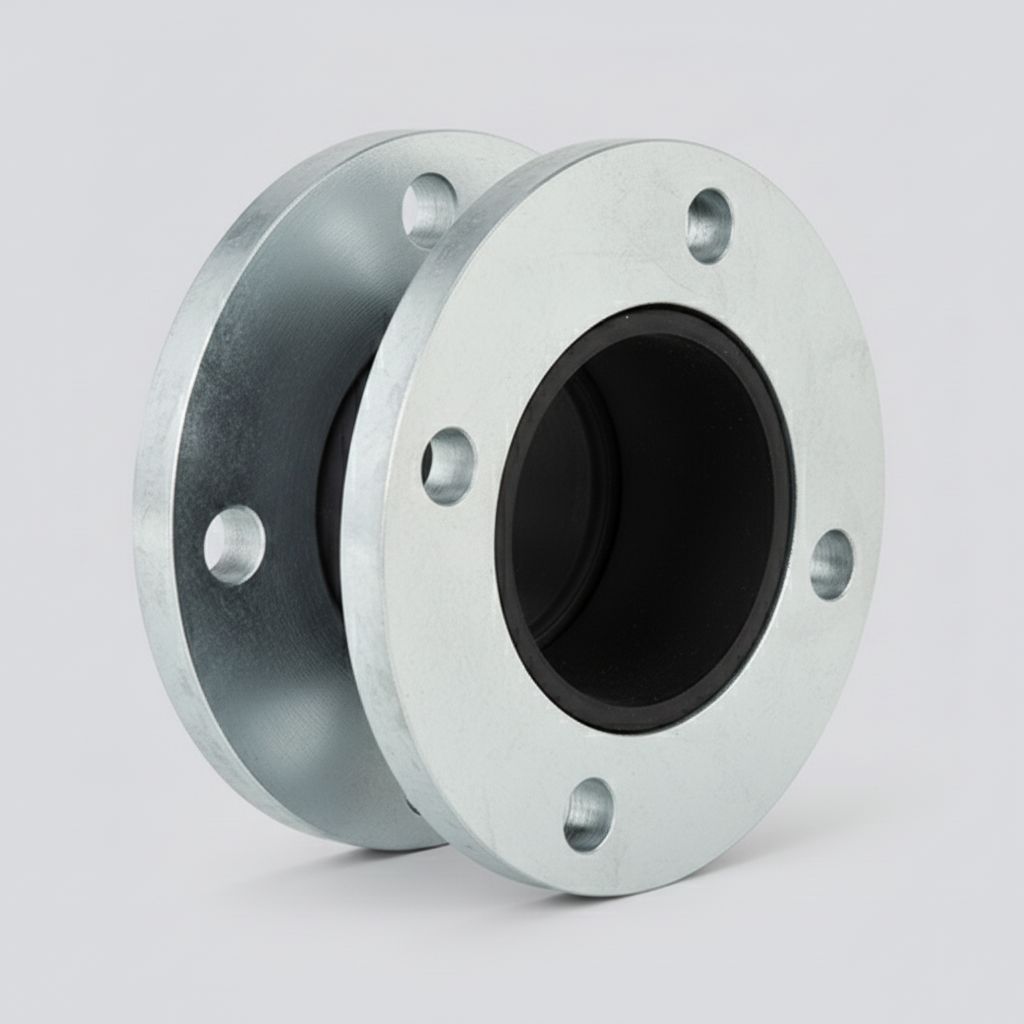

Vanox Rubber Expansion Joints

Rubber expansion joints (REJs) are critical mechanical components engineered to absorb vibration, compensate for thermal elongation, reduce noise transmission, and mitigate pressure fluctuations in industrial piping systems. Produced in several material configurations including EPDM, NBR, Neoprene, Hypalon, and Butyl, their design integrates elastomeric flexibility with reinforcement layers to achieve durability under dynamic mechanical loads.

Vanox, as a specialized manufacturer, focuses on flanged and threaded rubber expansion joints engineered for high durability, corrosion resistance, and vibration absorption in HVAC, industrial, and fluid transport applications. Modern industrial plants increasingly adopt elastomer-based expansion joints due to their ability to isolate mechanical stress, reduce fatigue at pump outlets, and extend the operational lifecycle of piping components.

Material Science of Rubber Expansion Joints

EPDM (Ethylene Propylene Diene Monomer) Rubber Performance

EPDM is one of the most used elastomers in expansion joints due to its resistance to hot and cold water, steam up to moderate pressures, UV radiation, ozone and atmospheric oxidation, and a wide range of diluted acids.

Mechanical Properties of EPDM

- Temperature range: –40°C to +120°C (short-term +140°C)

- Excellent flexibility and elastic recovery

- High vibration damping coefficient

- Low compression set

- Superior weather resistance

EPDM is especially preferred in HVAC, chilled water, hot water, boiler feed, and environmental engineering pipelines where chemical compatibility and heat stability are essential.

NBR (Nitrile Butadiene Rubber) for Oil and Hydrocarbon Service

NBR rubber is engineered primarily for applications involving petroleum oils, lubricants, diesel fuel, hydraulic fluids and greases.

Mechanical and Chemical Properties of NBR

- Temperature range: –20°C to +100°C

- Excellent resistance to hydrocarbons

- Good tensile strength and abrasion performance

- Ideal for industrial oil lines, fuel transfer lines, and compressor discharge circuits

|  |  |

|  |  |

Structural Composition of Vanox Expansion Joints

Multi-layer Elastomeric Architecture

A high-quality expansion joint is never a single rubber body. Vanox structures typically include:

- Inner Rubber Tube: Directly in contact with the working fluid. Designed for chemical compatibility and impermeability.

- Reinforcement Layers: High-tensile tire cord fabric, polyester or aramid fabric, helical steel wire (for vacuum-resistant designs).

- Outer Rubber Cover: Protects against ozone, weather, abrasion, and atmospheric corrosion.

Reinforcement Technology

Reinforcement layers determine burst pressure, fatigue resistance, axial, lateral, and angular movement capability, and vacuum resistance. Modern Vanox joints use tire-cord grade polyester or aramid reinforcement, which significantly improves cyclic load performance and prevents ballooning.

Flange Engineering and Metal Components

Stainless Steel Flanges (AISI 304 / 316)

Stainless steel flanges provide high corrosion resistance, temperature tolerance, durability in harsh industrial fluids, and long-term mechanical stability.

Carbon Steel Flanges with Hot-Dip Galvanization

Used for cost-optimized solutions. Zinc coating protects against galvanic corrosion, humidity-induced pitting, and atmospheric oxidation.

Design Parameters and Engineering Considerations

Axial Movement

Rubber expansion joints must compensate for thermal expansion, contraction, pump thrust forces, and misalignment during installation. Typical axial movement ranges: ±10 to ±15 mm depending on DN.

Lateral Deflection

Lateral movement is absorbed by the bellows geometry. Typical lateral tolerance: 8–20 mm depending on joint size and reinforcement design.

Angular Movement

Allows pipe direction changes under dynamic load without bending stress on flanges.

Pressure Performance

Performance is determined by elastomer hardness (Shore A), reinforcement angle, braid design, and molded radius geometry. Pressure classes include PN10, PN16, PN25. Burst pressure is usually 3× nominal pressure.

Vibration and Noise Attenuation Performance

Vibration Isolation Principle

Rubber has a high damping ratio due to its viscoelastic behavior. This reduces pump-generated vibration, mechanical noise transmission, structural resonance, and fatigue stress on piping supports.

Typical Frequency Response

Rubber expansion joints absorb frequencies between 15 Hz – 45 Hz. Most industrial pumps generate vibration within this range. This makes rubber joints essential in chiller plants, water booster pumps, HVAC systems, fire protection systems, and industrial compressors.

Threaded Rubber Expansion Joints

Application Areas

Used in small-diameter pump lines, HVAC fan coil units, booster pump connections, domestic water systems, and low-pressure industrial applications. Threaded connections are typically 1” to 2” and manufactured from brass or stainless steel.

Failure Modes and Engineering Prevention Techniques

Common Failure Types

- Torsional stress failure

- Overextension leading to cord separation

- Chemical incompatibility swell

- Pressure surges causing balloon deformation

- Vacuum collapse

Prevention Strategies

- Use control rods for limiting movement

- Install joints with proper pre-tension

- Check chemical compatibility

- Avoid torsional rotation during installation

- Maintain alignment within flange tolerances

Manufacturing Tolerances and Quality Assurance

Dimensional Tolerance Ranges

- Face-to-face length: ±2 mm

- Flange concentricity: <1.0 mm deviation

- Bolt hole tolerance: ±1 mm

Testing and Certification

Vanox typically performs:

Hydrostatic Pressure Testing

Performed at 1.5× nominal pressure.

Burst Testing

Determined until catastrophic failure to calculate safety factor.

Vacuum Testing

Ensures negative-pressure stability.

Fatigue & Cycle Testing

100,000+ cycles under bending, axial, and lateral loads.

Rubber Hardness Testing

Using Shore A durometer.

Adhesion Tests

Ensures bonding integrity between rubber and reinforcement fabrics.

Industrial Applications

HVAC and Chiller Systems

Critical for pump vibration isolation, thermal movement compensation, and noise reduction in commercial buildings.

Industrial Water Systems

Used in wastewater treatment, cooling towers, filtration systems, and RO plants.

Chemical and Petrochemical Plants

Especially NBR-based models for hydrocarbon resistance.

Marine and Shipbuilding Industry

EPDM and Neoprene models used for bilge lines, cooling water circuits, and pumping stations.

Advanced Testing, Analytical Modeling and Finite Element Analysis (FEA)

Beyond standard hydrostatic and burst testing, advanced validation of rubber expansion joints requires a combination of experimental testing and computational modeling. Finite Element Analysis (FEA) enables engineers to model the nonlinear, viscoelastic behavior of elastomers under combined loading: internal pressure, axial/lateral movement, and cyclic vibration. Vanox engineering teams typically run multi-physics simulations that incorporate:

- Nonlinear hyperelastic material models (e.g., Mooney–Rivlin, Ogden)

- Viscoelastic damping characteristics for time-dependent behavior

- Contact and frictional interactions with flange interfaces

- Thermo-mechanical coupling for high-temperature steam applications

FEA results are validated with full-scale fatigue tests in controlled test rigs. These rigs subject the joints to defined axial, lateral, and angular cycles under internal pressure to measure crack initiation points and life expectancy. Correlation between simulated and empirical S-N curves is critical for accurate lifecycle prediction.

High-Pressure and High-Temperature Performance

While typical REJs operate under moderate temperatures and pressures, specialized variants are designed for elevated conditions. For high-pressure service (PN25 and above), reinforcement density, wall thickness, and bonding quality are increased. High-temperature applications may use specialty elastomers or protective sleeves to prevent thermal degradation.

- High-pressure design emphasizes braid angle, ply count and steel cord integration to maintain burst margins.

- Thermal protection includes mica-based wraps, ceramic sleeves, or metallized shields for radiation protection.

- Steam-rated EPDM variants incorporate anti-aging additives and thicker outer covers to withstand oxidation.

Case Studies and Field Data

Real-world deployments provide insight into long-term performance. Notable case studies include:

Case Study A – District Heating Network

In a large district heating loop with DN250 mainlines, Vanox supplied EPDM flanged rubber expansion joints to reduce thermal movement and dampen pump-induced vibration. Over a 5-year monitoring period, joints demonstrated less than 3% permanent set and no leakage incidents, validating design assumptions.

Case Study B – Petrochemical Loading Arms

NBR threaded rubber expansion joints were installed on loading arms handling diesel and hydrocarbon blends. The joints exhibited excellent chemical resistance and required minimal maintenance over a 36-month service window, significantly reducing downtime compared to previous metallic compensators.

Lifecycle Engineering and Predictive Maintenance

Lifecycle engineering focuses on predicting service life and scheduling proactive maintenance. For rubber expansion joints, condition monitoring includes:

- Visual inspections for cracking, blistering, or adhesive failure

- Measurement of permanent set and dimensional drift

- Non-destructive testing for subsurface delamination

- Vibration analysis upstream and downstream of the joint to detect changes in damping behavior

Advanced predictive strategies incorporate sensor data (temperature, strain gauges) to forecast remaining useful life via machine learning models trained on historical failure datasets. These models can sharply reduce unexpected failures and optimize replacement schedules.

Installation Best Practices (Pro-Level Guidance)

Proper installation is paramount. Experienced installers follow these pro-level steps:

- Verify that pipeline supports and anchors are correctly positioned so the REJ does not carry pipe weight.

- Align flanges concentrically; use guide pins on large diameters to prevent misalignment during bolt tightening.

- Hand-tighten bolts in a star pattern, then torque to manufacturer recommendations using a calibrated torque wrench.

- Install movement limiter rods or sway braces in systems with excessive lateral or axial potential to prevent overextension.

- For buried applications, use protective boots and corrosion-resistant clamps.

Regulatory Environment and Standards Compliance

Compliance with standards ensures safety and interchangeability. Relevant standards include:

- DIN 4809 – Specifications for rubber expansion joints in heating systems

- EN 1092 – Flange standards

- ISO 9001 – Quality management for manufacturing processes

- FSA/ESA – Industry guidance for expansion joint selection and testing

Projects in petrochemical, marine, and power-generation sectors often impose additional client-specific approval steps: material traceability, batch testing reports, and third-party inspections (LR, DNV, TÜV).

Repair, Refurbishment and Replacement Strategy

Repair strategy depends on failure mode:

- Minor surface cracking: may be repaired with patching compounds if structural layers unaffected.

- Bondline delamination: generally requires replacement due to compromised safety margin.

- Flange corrosion: can be addressed by flange refurbishment if rubber body intact.

Replacement scheduling should be based on criticality: emergency shutdown components require proactive replacement at 60–70% of predicted life, while non-critical lines may adopt condition-based replacement.

Environmental Considerations and End-of-Life Handling

Elastomeric materials have environmental footprints. Vanox evaluates recyclability and implements end-of-life options:

- Mechanical shredding and reuse in non-structural rubber products

- Thermal recovery where local regulations permit

- Proper disposal according to waste management regulations for contaminated components

Designing for disassembly (e.g., separable flanges, reusable metal parts) improves recyclability and reduces lifecycle environmental impact.

Advanced Topics: Custom Solutions and Hybrid Designs

For complex challenges, hybrid solutions combine rubber expansion joints with metallic elements—such as short metal bellows sections for axial stiffness combined with rubber sections for vibration isolation. These hybrid assemblies leverage the strengths of each material class to meet demanding pressure, movement, and longevity targets.

Summary and Key Takeaways

- Rubber Expansion Joints offer superior vibration isolation, thermal movement compensation, and noise reduction capabilities compared to fully metallic alternatives.

- Material selection (EPDM vs NBR) is driven by fluid compatibility, temperature ranges, and expected mechanical loads.

- Advanced FEA coupled with full-scale fatigue testing provides reliable lifecycle predictions and reduces conservatism in design.

- Proper installation, proactive maintenance, and adherence to standards (DIN, EN, ISO) are essential to achieving design life.

- Hybrid and custom solutions enable REJs to be used in higher pressure and more aggressive environments where standard designs would fail.

Conclusion

Vanox Rubber Expansion Joints are engineered to meet the complex demands of modern piping systems. From material science and reinforcement technology to advanced testing, FEA validation, and lifecycle management, REJs represent a mature yet evolving technology. For projects requiring vibration damping, thermal movement control, or improved operational reliability, well-specified rubber expansion joints—combined with correct installation and proactive maintenance—offer cost-effective, durable, and environmentally considered solutions.

Keywords: Rubber Expansion Joint, rubber Vibration Absorption, Stainless Steel Flanged Rubber Expansion Joint, threaded rubber Expansion Joint, rubber Vibration Absorption Expansion Joint, EPDM Expansion Joint, NBR Expansion Joint.

Rubber Expansion Joints – Frequently Asked Questions

Below are the most common questions related to rubber expansion joints, covering installation, material types, lifespan, and performance factors.

Below are examples of non-metallic fabric expansion joints manufactured by Vanox for high-temperature duct systems.