The Unsung Heroes of Construction: A Deep Dive into Expansion Joints

In the intricate world of construction and engineering, certain components work tirelessly behind the scenes, ensuring the longevity and integrity of our structures, often without getting the recognition they deserve. Among these vital yet often overlooked elements are expansion joints. Far from being a mere accessory, these critical components play a paramount role in managing the dynamic forces that act upon buildings, bridges, pipelines, and pavements every single day. So, what exactly are expansion joints, and why are they so crucial? Let’s delve into their comprehensive definition, critical importance, diverse types, applications, and the factors influencing their performance.

What is an Expansion Joint?

An expansion joint (also known as a movement joint or construction joint) is a meticulously engineered mid-structure separation designed to accommodate various forms of movement. Primarily, it absorbs the thermal expansion and contraction of building materials, but also addresses other dynamic forces such as seismic activity, wind sway, vibration, and differential settlement. Without these deliberately incorporated gaps, the immense stresses generated by these movements could lead to severe cracking, buckling, and ultimately, catastrophic structural failure.

Consider this: common construction materials like concrete, steel, and asphalt significantly expand when heated and contract when cooled. A long bridge on a hot summer day might stretch several inches, while in freezing winter, it will noticeably shrink. An expansion joint provides the necessary space for these dimensional changes to occur harmlessly, preventing destructive internal stresses within the structure.

Kompansatör: A Specialized Type of Metal Expansion Joint

The term Kompansatör (often translated as “Compensator”) specifically refers to flexible metal bellows components designed to absorb dimensional changes caused by thermal expansion or contraction in piping systems that carry hot or cold fluids, or are exposed to significant ambient temperature fluctuations. The primary purpose of Kompansatörs is to resolve thermal expansion and vibration issues in pipe lines. With their inherently flexible structure, Kompansatörs effectively absorb thermal expansion and vibrations, thereby relieving stress on the entire piping system. The rigidity of the corrugated (bellows) section of a Kompansatör is exceptionally low and can be considered negligible compared to the pipeline itself. For this reason, Kompansatörs are often referred to as ‘zero-load’ elements. The stresses arising from the thermal expansion of the pipeline are absorbed and compensated by these resilient convolutions. A well-designed Kompansatör bellows can achieve a service life of 1000 cycles when operated within its allowed movement range. Factors influencing the service life of Kompansatörs include:

- Temperature: Extreme or rapidly changing fluid temperatures.

- Movement: The magnitude and frequency of axial, lateral, or angular movements.

- Pre-setting (Pre-tensioning): Correct initial installation alignment and pre-stress.

- Stress Cycle Frequency: How often the joint undergoes movement cycles.

- Operating Pressure: The internal pressure of the fluid.

- Pressure Shock and Surges: Sudden and significant pressure changes.

- Thermal Shock: Abrupt temperature changes.

- Installation Quality: Proper alignment and secure mounting are paramount.

- Corrosion: Exposure to corrosive fluids or environments.

Kompansatörs have an extremely wide range of applications, commonly used in pipe installations, thermal pressure vessels, and across transportation and industrial sectors. They are manufactured to absorb various movements in pipes carrying all types of substances, across every diameter, pressure, and temperature range.

Why Are Expansion Joints So Important?

The critical functions of all expansion joints, including Kompansatörs, encompass:

- Preventing Cracking and Stress: They alleviate internal stresses generated by thermal changes and other movements, thereby preventing unsightly and structurally damaging cracks.

- Accommodating Movement: They allow for movement due to temperature fluctuations, seismic events, wind sway, and the natural settling of a structure.

- Protecting Waterproofing: In roofs and decks, they ensure the integrity of waterproofing membranes, preventing leaks and associated damage.

- Enhancing Durability and Longevity: By effectively managing movement, expansion joints significantly extend the lifespan of the entire structure, drastically reducing long-term maintenance costs.

- Ensuring Safety: In critical infrastructure like bridges and roadways, they help maintain a smooth, even, and safe surface for traffic, minimizing hazards.

- Vibration and Noise Isolation: Especially non-metallic types, they can effectively dampen vibrations and reduce noise transmission in piping systems.

Comprehensive Types of Expansion Joints

Expansion joints are broadly categorized into Metal Expansion Joints and Non-Metallic Expansion Joints, each with specialized sub-types.

Metal Expansion Joints (including Kompansatörs)

These are predominantly used in piping, ducting systems, and industrial applications where high temperatures, pressures, or aggressive media are encountered.

- Metal Bellows Expansion Joints: The most prevalent type of Kompansatör, featuring flexible corrugated metal sections (bellows) that flex to absorb movement. They can be designed for axial (along the pipe axis), lateral (perpendicular to the pipe axis), or angular (rotational) deflection.

- Externally Pressurized Expansion Joints: In these Kompansatörs, the internal fluid pressure acts on the outside of the bellows, preventing squirm or instability, making them ideal for high-pressure applications where stability is critical.

- Dilatation & Earthquake Expansion Joints: Specifically engineered to accommodate substantial building settlement, significant thermal movements, and particularly large seismic displacements, ensuring structural integrity during ground movement.

- FM Approved Omega Loop U&V Flex: These are typically pre-fabricated pipe loops with inherent bends, offering extreme flexibility for very large movements. They are frequently used in fire protection systems due to their Factory Mutual (FM) approval, which certifies specific performance standards for critical safety applications.

- Decorative Type Expansion Joints: While fully functional, these Kompansatörs are designed with aesthetic considerations in mind for visible areas in architectural installations, aiming to blend seamlessly with the building’s design.

- FM Approved Dilatation & Earthquake Expansion Joints: Similar to the non-FM approved version, but certified by Factory Mutual (FM) for specific performance standards, often mandated in critical infrastructure and safety-sensitive environments.

- Pressure Balanced Metal Expansion Joints: These Kompansatörs are uniquely designed to eliminate or significantly reduce the pressure thrust forces on adjacent equipment and anchor points, making them indispensable for systems sensitive to force loads.

- Lens Type Expansion Joints: Characterized by a smoothly curved, lens-shaped profile, these Kompansatörs offer a robust design often utilized in specific industrial applications requiring particular stiffness and movement characteristics.

- Rectangular Expansion Joints: Unlike circular bellows, these Kompansatörs are designed with rectangular profiles for use in large ducting systems carrying hot gases, commonly found in power generation plants, industrial furnaces, and process exhaust systems.

Non-Metallic Expansion Joints

These types offer superior flexibility, chemical resistance, and are often a cost-effective solution in various structural, HVAC, and less aggressive piping applications.

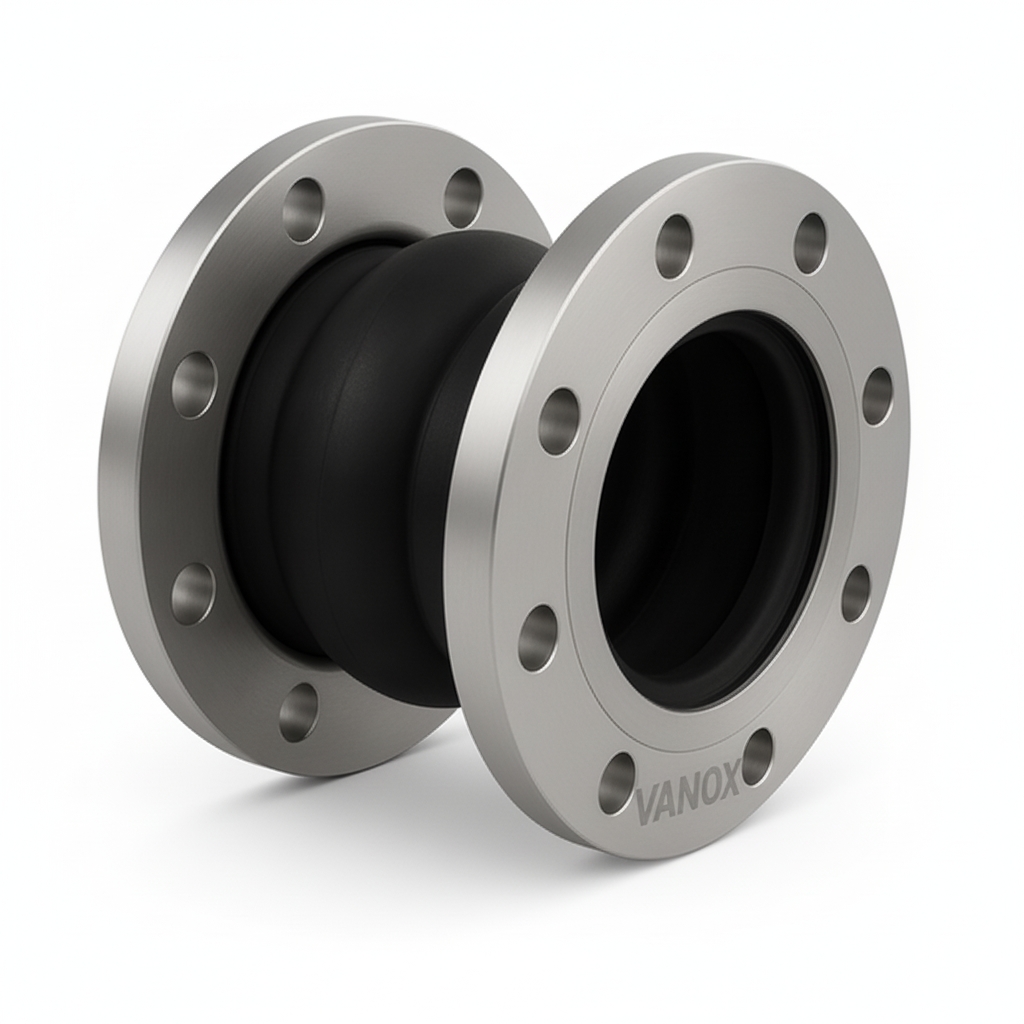

- Rubber Expansion Joints: Highly versatile, manufactured from various synthetic elastomers (e.g., EPDM, Neoprene, Nitrile, Butyl) based on chemical compatibility and temperature range. They excel in vibration isolation, noise reduction, and absorbing movements in piping systems, finding widespread use in water and wastewater treatment, HVAC systems, and general industrial processes.

- Teflon (PTFE) Expansion Joints: Renowned for their exceptional chemical resistance to a broad spectrum of aggressive media and high-temperature capabilities. They are the material of choice for highly corrosive chemical applications where other materials would quickly degrade.

- Fabric Expansion Joints: Primarily employed in ducting systems (especially those conveying hot air, flue gases, or low-pressure media), these are constructed from multiple layers of high-temperature resistant fabrics, insulation materials, and often a gas barrier. They are lightweight, extremely flexible, and can accommodate large movements, misalignments, and vibrations in large cross-section ducts.

Connection Types for Expansion Joints (Kompansatörs)

The method of connecting expansion joints to the piping system is crucial for proper function and ease of installation/maintenance.

- Flanged Connection: Standard manufacturing typically uses flanges according to DIN 2501 standards in the 16 bar pressure category. Upon request, flanges conforming to ANSI, BS standards, different pressure ratings, or even special materials can be manufactured. The connection of flanges to the expansion joint component can be:

- Swivel Flanged: Allows for easier alignment during installation.

- Fixed Flanged: A permanent, robust connection.

- Welding Neck Flanged: Provides a smooth transition to the pipe, ideal for high-pressure systems.

- Welding Neck Connection: Used in installations where welding is not problematic and the pipeline itself is welded. The disadvantage arises during removal, as the Kompansatör must be cut out.

- Threaded Connection: Commonly used in the heating systems of multi-story buildings, particularly in riser lines, to accommodate pipe contraction and expansion, provide sound insulation, and correct pipe misalignments. These can be normal or decorative types.

- Grooved Connection: Provides ease of use in areas where welding is not feasible. The ability to easily install and remove components allows for targeted interventions in the system, and is often used for earthquake protection applications in piping.

Other Accessories for Expansion Joints

To enhance performance, protection, and functionality, expansion joints often integrate additional accessories:

- Liners (Inner Sleeves): An internal sleeve fitted within the bellows. Liners are mandatory in the following situations:

- To reduce fluid friction losses.

- If the fluid velocity is very high, causing bellows to vibrate at near-resonance frequencies.

- In environments with catalysts or highly acidic media, where there is a risk of erosion.

- If reverse flow occurs.

- When fluid temperatures are very high, to protect the bellows directly from extreme temperatures and preserve its physical properties.

Liner design is dependent on the nominal diameter of the Kompansatör, fluid velocity, and liner length, and is typically performed by the manufacturer. If the fluid direction is vertical, liners should have drainage holes at the bottom to prevent potential accumulation between the liner and the convolutions.

- Protective Covers (Outer Sleeves/Shipped Covers): These covers shield the bellows of the Kompansatör from mechanical damage (e.g., impact, abrasion) and external environmental factors. If the Kompansatör also requires insulation, the insulation material should be applied around the protective cover.

- Limit Rods: Used with lateral Kompansatörs to prevent unwanted excessive movements beyond their design capacity. If these rods remain partially uninsulated or completely exposed, they are less susceptible to thermal stresses.

- Main Anchors/Fixed Guides: These anchor plates are used to absorb the pressure forces generated within the pipe. Guides are used to maintain the desired alignment and direction of the pipeline. Forces that main anchors must withstand include:

- Pressure force (thrust due to internal pressure).

- Pipe friction.

- Centrifugal force (in curved pipes).

- Force arising from the spring constant of the bellows.

Important Note: Liners should generally not be used with highly viscous fluids. Such fluids can solidify and lead to premature fatigue and failure of the Kompansatör.

Types of Movement Absorbed

Expansion joints are designed to absorb various types of movement, either individually or in combination:

- Axial Movements: Movement along the longitudinal axis of the pipe or structure (compression or extension).

- Lateral Movements: Movement perpendicular to the longitudinal axis (side-to-side displacement).

- Angular Movements: Rotational movement around an axis.

- Combined Movements: A combination of axial, lateral, and/or angular movements.

- Vibrations: Absorbing dynamic movements caused by system dynamics, such as pump or machinery vibrations.

Characteristics of a Properly Selected and Installed Expansion Joint

A correctly selected and properly installed Kompansatör/expansion joint exhibits the following crucial characteristics:

- Resistant to Pressure and Vacuum: Capable of withstanding the specified internal pressures and vacuum conditions.

- Temperature Resistant: Designed to perform reliably across the full range of operating temperatures.

- Long Service Life: Engineered for extended operational longevity, reducing replacement frequency.

- Corrosion Resistant: Materials selected to withstand corrosive fluids or environmental conditions.

- Maintenance-Free: Requires minimal to no ongoing maintenance, reducing operational costs.

- Economical: Provides a cost-effective solution for managing movement and stress over its lifespan.

The core element of any Kompansatör is its flexible corrugated (bellows) section. The material thickness, pitch (distance between convolutions), height, and other structural properties of the convolutions are meticulously designed as a holistic response to the pipeline’s operating conditions, including pressure, temperature, expansion, vibration, and fluid characteristics. Cr-Ni austenitic stainless steel is predominantly used as the bellows material. A key characteristic of this material is its “cold working” property, which increases its yield strength as it undergoes cyclic deformation during operation. In situations involving very high operating pressures and the need to achieve specific flexibility, multi-ply convolution applications are utilized. Stresses in multi-ply bellows are generally lower than in single-ply bellows because the flexible cross-section distributes the stress across multiple layers, enhancing durability and performance.